To make the millions of batteries that we have without a single manufacturer-caused catastrophic failure in the field is a testament to how quality is ingrained in all facets of Totex’s processes and company culture.

Quality Control

Totex’s quality systems have been shaped by our many years of working with the world’s leading medical device manufacturers. As you might imagine, catastrophic failures in the hands of an end user is not an option in the medical device industry.

Our quality systems are held to a much higher standard than most other battery manufacturers and we are continually being audited to the toughest quality criteria. This is how we are able to achieve an overall DPPM of less than 500 on average.

Certifications and Compliance

- ISO 9001

- ISO 13485

- ISO 14001

- FDA Registered line

- QC 08000

- IPC610D

- REACH

- WEEE

- RoHS

- Conflict minerals, EICC / GeSI

- Class 9 Dangerous Goods

Other Quality Controls

- FMEA, MTBF, DVT plans

- Microscopic visual inspection of all SMT solder points

- Statistical Process Control on all major assembly processes

- Real-time line failure monitoring

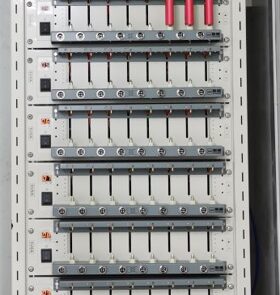

- 2000 calibration cycle channels for pre-shipment battery testing

- Six Sigma training

- MSA Cross, Nest & Attribute GR&R

- J-STD-001 IPC Certified trainers • and assemblers

- BSI certified Internal Auditors – ISO 13485 Std

- ESD control training & verification

Mission Statement

Our mission is to strategically grow while maintaining our reputation of having fast customer response times, technical expertise, and a culture of high quality and efficiency leading to the design and manufacture of high quality batteries and chargers at competitive prices.