After designing and manufacturing batteries and charging solutions for hundreds applications across many industries, Totex has the battery knowledge and experience that your company can depend on.

Choosing The Right Cell

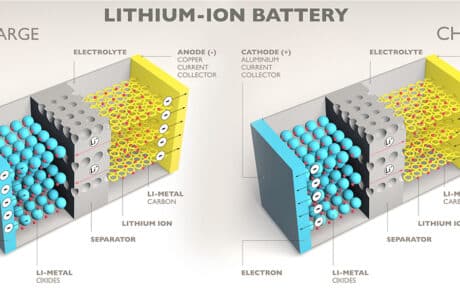

Every dependable, high-quality battery starts with choosing the right cell. In the battery manufacturing business, a battery (or “battery pack”) is composed of cells, a protection circuit, a fuel gauge, an enclosure, connectors and possibly other electronic components. Cells are at the heart of any battery.

They determine what voltage your device will be supplied with, how much current it can draw, and how long your device will run.

Choosing the right cell chemistry for your application is the first step. Totex has been working with rechargeable cells since before Lithium Ion cells were first widely available for commercial use.

We have experience with LiFePO4, NiMH, Li-SOCl2, SLA and primary (non-rechargeable) cells of various chemistries as well. As experienced users of Lithium Ion batteries know, you can’t just look online and choose any battery that fits in your portable device. There are only a few cell manufacturers that consistently produce high quality cells with minimal variation from cell to cell. We call these manufacturers “Tier 1” suppliers.

There is also the issue of future availability of these cells. Just because a cell is made by the tens of millions by a manufacturer doesn’t mean that it will still be in mass production a year from now.

Totex has been working with all Tier 1 cell manufacturers for decades and we regularly visit their facilities. We have evaluated many of the biggest Tier 2 manufacturers, as well as a few custom cell manufacturers.

Totex knows cells and the cell marketplace. From years of extensive testing, we have created and maintain an extensive database of cell performances so that our knowledge of a cell is not limited to datasheets. We pride ourselves on being able to choose the best cell for your application.

DESIGNING THE PACK

High-quality battery pack production requires extensive experience in all aspects of design and manufacturing. Having designed thousands of batteries and producing millions each year, Totex’s design prowess and manufacturing capabilities have been thoroughly vetted.

To have a full understanding of the potential technical pitfalls early in the concept phase of a battery, there are several areas one must have expertise in:

ELECTRONICS

A battery always includes protection circuitry, along with optional features like fuel gauges, cell balancing, on-board charging circuits, MCUs, LEDs and firmware.

It takes many years of experience to understand the nuances of the various battery management and protection IC’s on the market.

COMMUNICATIONS

Totex has experience with whatever communication protocol you need: SMBus, I2C, Single-Wire, HDQ, RS232, etc. Or, if you need conversion firmware to make these protocols talk to each other, Totex has the know how to ensure your battery and host device have flawless communication.

ENVIRONMENTAL CONCERNS

Totex’s engineers are experts in dealing with electrical and mechanical performance issues due to temperature, water or dust intrusion, shock, and vibration.

We perform our environmental testing in-house, allowing for fast turn-arounds when you need test results quickly.

ENCLOSURES

Because we do our own injection molding and make our own injection mold tools, we have good insight into what geometries, wall thicknesses, and materials are best for the structural integrity of your design.

This experience is also helpful in determining the manufacturability of your conceptual design.

OPERATING ENVIRONMENT

Most Lithium Ion batteries do not like extreme temperatures. High temperatures can shorten a battery’s life and cold temperatures can severely degrade performance. Totex keeps an extensive database of cell performance over temperature and with various loads.

Along with our long history of working with applications involving temperature extremes, waterproof requirements, harsh vibrations, and other severe conditions, we have the design experience to ensure your device operates reliably in the most extreme environments.

DESIGNING THE CHARGER

As with batteries, Totex designs and manufacturers all of our own chargers, including integrating the charging circuitry into the battery itself. This means we have a thorough understanding of the battery-charger communications interface, as well as the incompatibilities that might exist between fuel gauges and charging chips.

As can be seen on our charger page, we have full charger design, manufacturing, and testing capabilities in-house. It’s not merely something we can do for an occasional customer as an add-on. It’s an integral part of almost every battery we make.

HOST REQUIREMENT

In our 35+ years of battery design, we have dealt with just about every industry that uses rechargeable batteries. This means that there is a good chance we already have some knowledge of what the voltage and current considerations are for your application.

Whether the design consideration involves back EMF from a motor, heat generation from inside the host device, noise immunity, battery insertion or removal, or any of the myriad of things that go into optimizing a battery design.

END USER EXPERIENCE

End user experience is often the top priority of our customers. Poor battery performance can ruin the reputation of an otherwise successful product and a catastrophic battery failure can create a PR nightmare and years of legal issues.

It pays to partner with a manufacturer that has extensive experience in all facets of battery and charger design and manufacturing to ensure your device operates.

Mission Statement

Our mission is to strategically grow while maintaining our reputation of having fast customer response times, technical expertise, and a culture of high quality and efficiency leading to the design and manufacture of high quality batteries and chargers at competitive prices.